Cold-Resistant Foldable Container House

Product Specifications

Dimensions: Standard dimensions are 5800mm in length x 2500mm in width x 2560mm in height, with internal dimensions of 5620mm in length x 2260mm in width x 2440mm in height.

Frame: Made from thickened galvanized steel materials to enhance stability and durability in low-temperature environments.

Walls: Utilize thickened rock wool boards, at least 50mm thick, to provide additional insulation.

Roof: Composed of 0.45mm thick cover steel plates, 40mm thick glass wool, and 0.3mm thick ceiling steel plates to ensure good heat insulation and waterproof performance.

Floor: Made of T16mm chlorox magnesium fireproof floor, providing a solid base and preventing ground cold air penetration.

Side Panels: All outer/end panels use 8kg 50mm 0.236 foam sandwich panels, with a frame of T1.2mm Q235 galvanized steel pipes.

Doors and Windows: Including 1 exterior door and 2 aluminum alloy white single-sided sliding windows, with dimensions of 977mm x 2360mm and 930/1200mm.

Folding Hinges: Using T3mm 180x76 galvanized hinges to ensure smooth folding even in low temperatures.

Electrical System: Includes CE certified electrical products to ensure safety and reliability.

Raw Materials

Galvanized Steel: Used for frames and hinges to enhance corrosion resistance and strength.

Rock Wool Board: Used for walls to provide good heat insulation and thermal retention.

Foam Sandwich Panels: Used for side panels and roofs to enhance thermal insulation.

Chlorox Magnesium Fireproof Floor: Used for the floor to provide fireproof and thermal insulation properties.

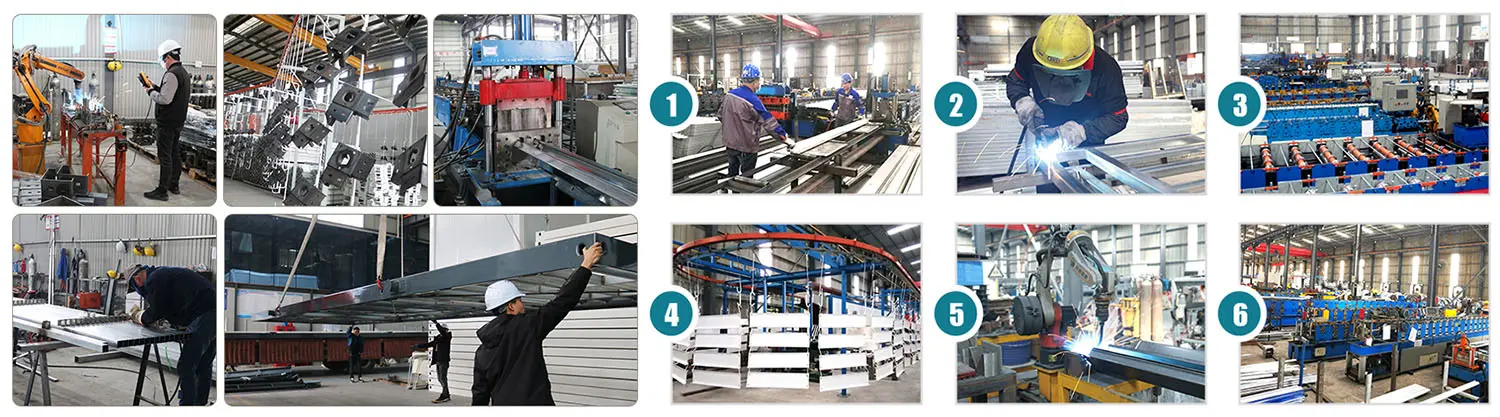

Production Process

Cutting and Welding: Advanced cutting and welding techniques are used to ensure precise cutting and solid welding of materials.

Assembly: Assembled in a strictly controlled environment to ensure precise fitting of all components.

Insulation and Thermal Treatment: Additional insulation materials are added to walls and roofs to improve cold resistance.

Quality Inspection: Quality checks are conducted at every stage of the production process to ensure high standards of the product.

Usage Scenarios

Extreme Cold Regions: Suitable for temporary housing, workstations, or warehouses in extremely cold areas.

Construction Sites: As temporary offices or worker dormitories on construction sites.

Emergency Relief: As emergency relief stations or temporary shelters during natural disasters.

Outdoor Activities: As temporary facilities for outdoor activities, such as accommodation units in ski resorts.

Quality Inspection

Material Testing: All raw materials are rigorously tested to ensure they meet cold resistance standards.

Structural Testing: The finished product undergoes structural strength testing to ensure stability in extreme low temperatures.

Insulation Performance Testing: Insulation materials are tested to ensure their effectiveness in low-temperature environments.

Packaging and Transportation

Packaging: Moisture-proof and frost-proof packaging materials are used to ensure that the product is not damaged during transportation.

Transportation: Special transportation methods, such as refrigerated containers, are used to protect the product from extreme temperature impacts.

After-Sales Service

Installation Guidance: Detailed installation guidance is provided to ensure customers can correctly install and use the product.

Repair Services: Professional repair services are offered to address potential malfunctions and damages.

Customer Consultation: Customer consultation services are provided to answer questions about product use and maintenance.

Payment Settlement

Contract Signing: A certain percentage of the prepayment is required after the contract is signed.

Goods Acceptance: The customer conducts an acceptance upon arrival of the goods and pays the remaining amount after confirmation.

Invoice Provision: A formal value-added tax (VAT) invoice is provided for financial processing by the customer.