Flat Pack Container House: A Flexible and Efficient Housing Solution

Product Parameters

The flat pack container house typically measures 6 meters in length, 3 meters in width, and 2.5 meters in height, providing approximately 18 square meters of living space per unit. Multiple units can be stacked or combined to create larger living or working spaces. The flat pack design enables the entire structure to be packed into a compact form for transportation, with each unit weighing between 1.5 to 2 tons, depending on customizations.

Raw Materials

Constructed from high-quality steel, the flat pack container house is designed for durability, structural stability, and weather resistance. The walls are made of insulated sandwich panels with polyurethane or rock wool for thermal insulation and soundproofing. Clients can choose from a variety of interior and exterior finishes, including wood, steel, or PVC cladding. The floor is typically made from reinforced plywood or cement board for extra durability.

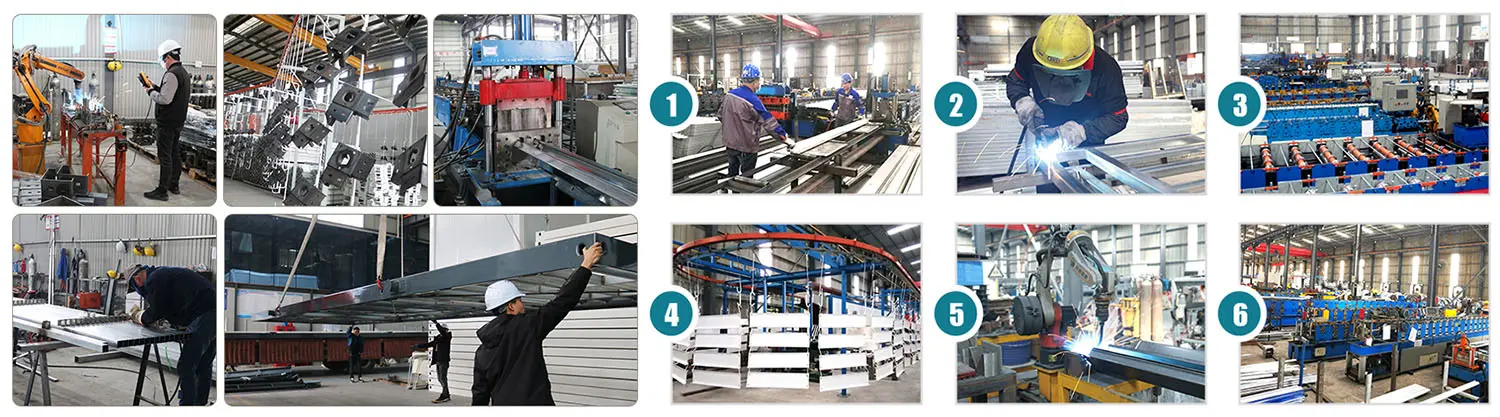

Production Process

The production of the flat pack container house involves several key steps:Frame Fabrication: The steel frame is designed and welded to create the basic structure of the unit.Panel Installation: Insulated sandwich panels are installed to provide thermal efficiency and soundproofing.Interior Finishing: The interior is customizable, allowing for different layouts and materials, including flooring, cabinetry, and partition walls.Electrical and Plumbing Installation: Pre-installed wiring and plumbing are added according to client specifications, allowing for quick hook-ups on-site.Quality Control: Rigorous tests are conducted to ensure the structural integrity, insulation performance, and overall finish of each unit.

Application Scenarios

The flat pack container house is versatile and suitable for various applications, including:Temporary Housing: Ideal for disaster relief, refugee camps, or construction sites, where quick setup and mobility are essential.Modular Homes: Multiple units can be combined to create larger, permanent homes with customizable layouts.Office Spaces: The flat pack container house can serve as temporary or permanent office spaces, with options for meeting rooms, workstations, and more.Vacation Homes: It’s perfect for use as a holiday home, providing a quick and cost-effective way to build in remote locations.Mobile Clinics or Classrooms: These units are ideal for rapid deployment as medical or educational facilities in emergencies or underserved areas.

Quality Inspection

Quality inspection is a crucial part of the production process. Each unit undergoes thorough evaluations for:

Structural Integrity: Ensuring the steel frame can withstand heavy loads and environmental conditions.

Insulation and Soundproofing: Testing the effectiveness of the insulated panels for thermal regulation and noise reduction.

Finishing Quality: Inspecting the durability and aesthetic appeal of the interior and exterior finishes.

Packaging and Transportation

One of the key advantages of the flat pack container house is its efficient packaging. Each unit is disassembled into flat sections for easy transportation, allowing multiple units to be shipped in a single container. The parts are securely packed with protective materials to prevent damage during transit. Once on-site, the flat pack container house can be assembled quickly with minimal equipment.

After-Sales Service

Customers purchasing the flat pack container house benefit from comprehensive after-sales support, including:Warranty Coverage: A standard warranty covering structural and material defects for one year.Technical Support: A dedicated team is available to provide guidance and troubleshooting during assembly and usage.Replacement Parts: In the event of damage or wear, replacement parts can be provided quickly to ensure minimal downtime.

Payment Settlement

Flexible payment options are available to clients interested in acquiring a flat pack container house. Typically, a 30% deposit is required to initiate production, with the remaining balance due upon completion and delivery. Various payment methods, including bank transfers and letters of credit, are accepted, providing convenience and security for clients.

Conclusion

The flat pack container house is an ideal solution for those seeking a cost-effective, flexible, and durable housing option. Its modular design allows for rapid assembly and customization, making it suitable for a wide range of applications, from temporary housing and mobile offices to permanent homes and vacation properties. With its efficient packaging, high-quality materials, and modern design, the flat pack container house offers a versatile and sustainable approach to modern living.